Products

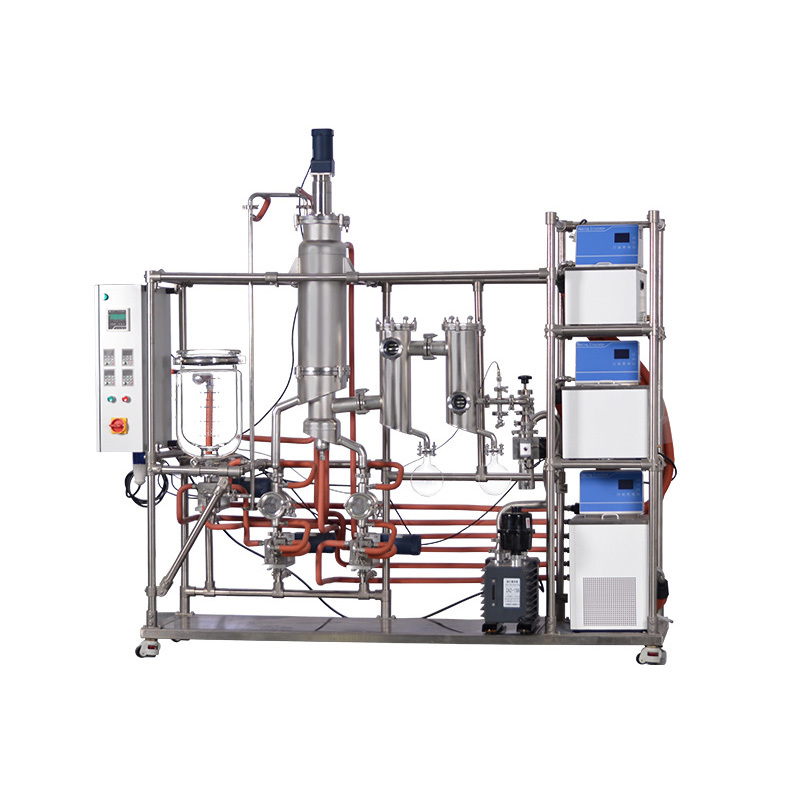

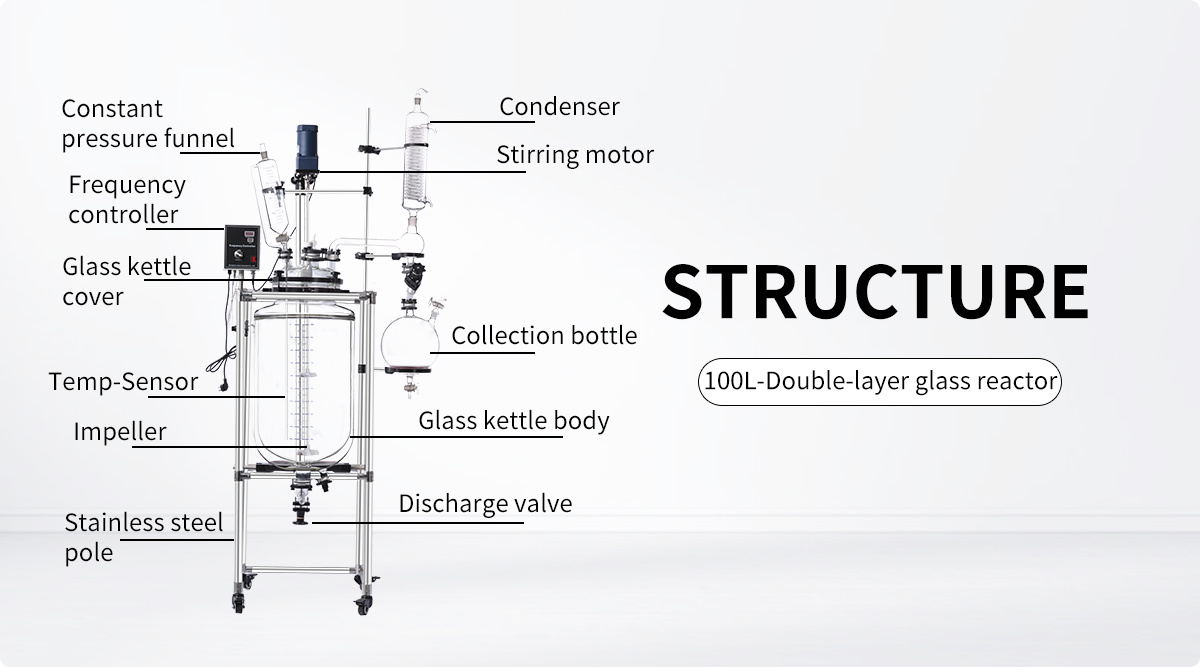

GR-100L Glass Reactor

The reaction solvent can be placed inside the glass reactor for stirring reaction, and the interlayer can be flushed into the heat transfer oil for circulation. The interlayer of the glass reactor can provide high-temperature reaction; Glass reactor can also be used for low-temperature reactions; Glass reactor can be evacuated and subjected to negative pressure reactions.

keyword: constant temperature;Reaction bath

Classification: Chemical Reactor

- Product Description

-

Model

GR-100L

Volume(L)

100

Jacket volume(L)

30

Condensation area(m²)

1.1

Feeding tank volume(L)

2L

Recovery tank volume(L)

20

Kettle cover diameter

Impeller diameter

60# flangetype

Temperature sensor diameter

40# flangetype

Condenser connection

50# spherical grinding

Liquid feed inlet

34# standard grinding×1

Feeding tank interface

40# standard grinding

Solid feed inlet

80# flangetype

Glass assembly

High borosilicate glass 3.3

Main frame

SUS304

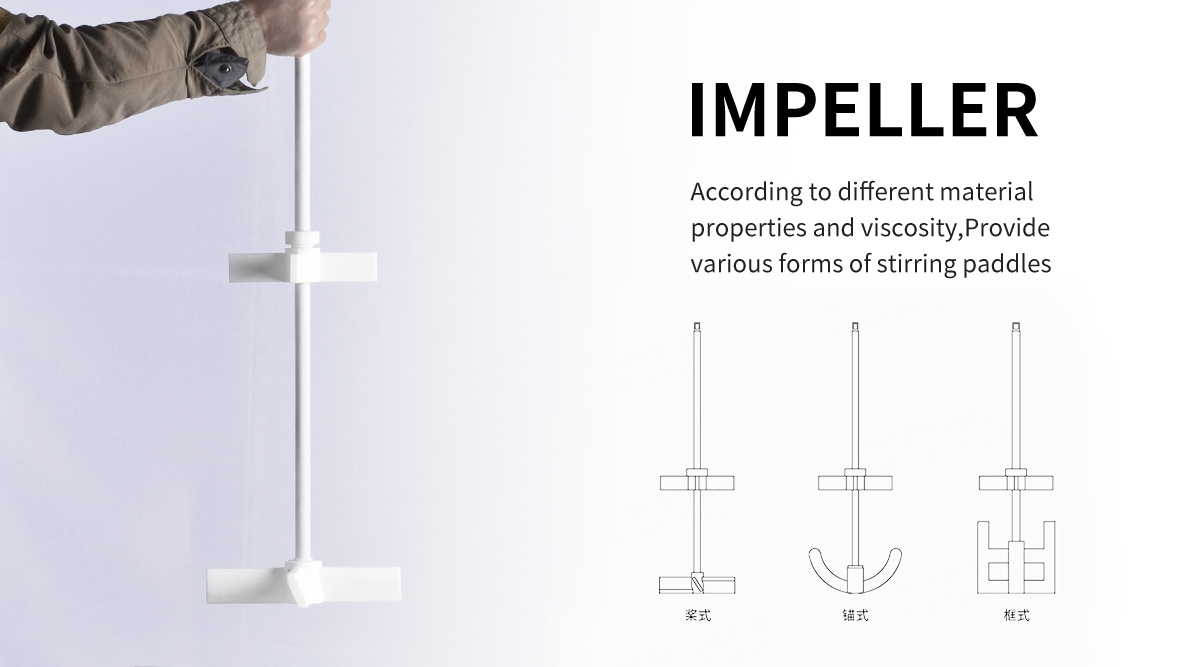

Stirring paddle

Paddle agitator, internal stainless steel, external polytetrafluoroethylene (PTFE), titanium

Motor

For viscous materials, high-power motors can be used

Move method

Lockable casters

Working temperature(℃)

-120℃~300℃

Maximum temperature difference(℃)

≤60

Pressure in kettle(MPa)

-0.1~0.1

Jacket pressure resistance(MPa)

≤0.1

Pressure rise rate of vacuum system

≤2kPa/h

Mixing motor power(W)

Common 200W/ explosion proof 370W

Speed regulation mode

Frequency control

Speed adjustment range(rpm)

0~600

Temperature sensor

PT100

Temperature display accuracy(℃)

±0.1

Temperature range

Water: RT~90℃

Oil: RT~300℃

Interface size of stainless steel insulation hose

½in external screw thread

Seal material

PTFE

Installation height of discharge valve(mm)

450

Power

220V/110V,50/60Hz

Environment temperature(℃)

5~35

Relative humidity(%)

≤ 65

Size(mm)

800W×710D×2600H

Weight(kg)

128

Previous Page

Next Page

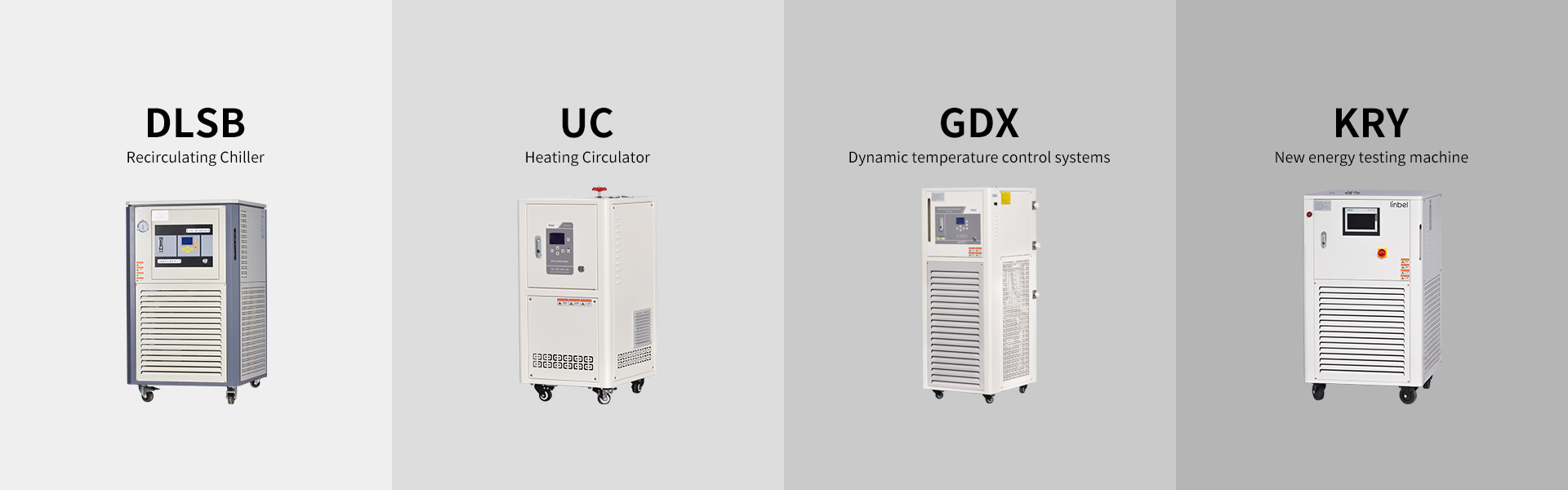

Related Products

Message consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!