Products

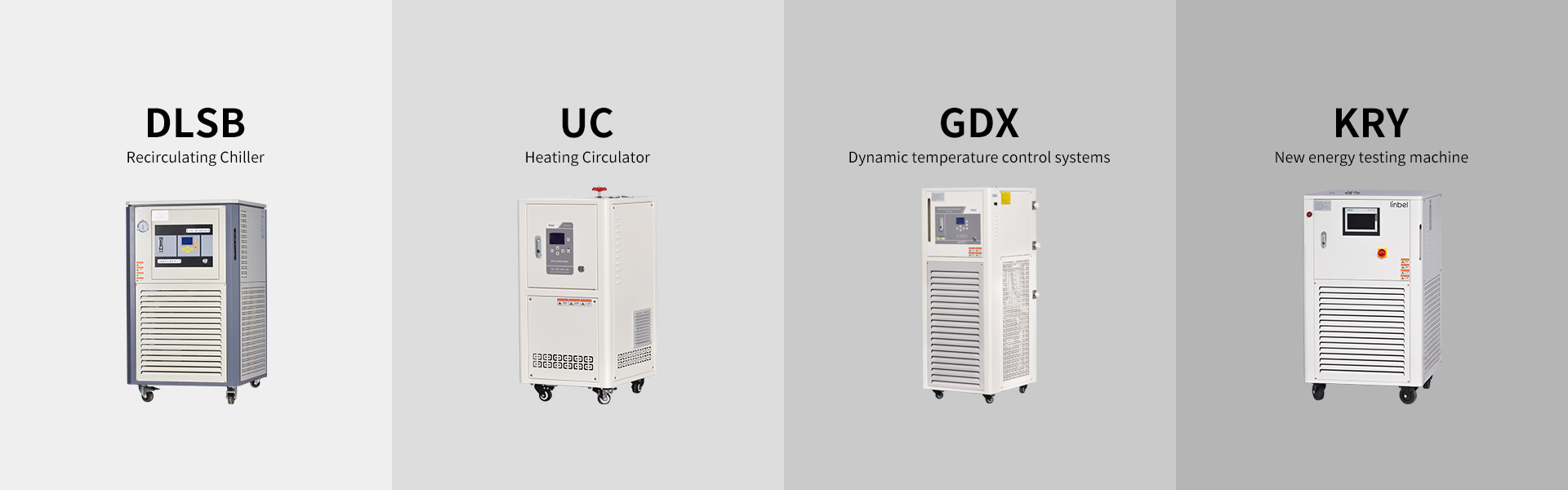

-30~200℃ Dynamic Temperature Control System

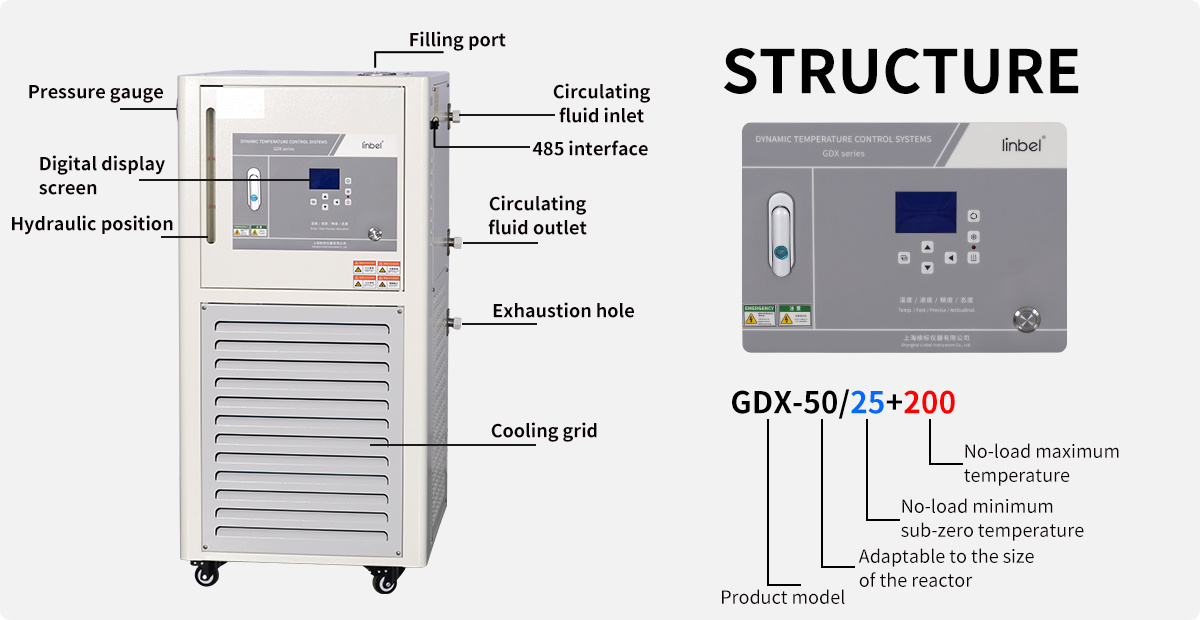

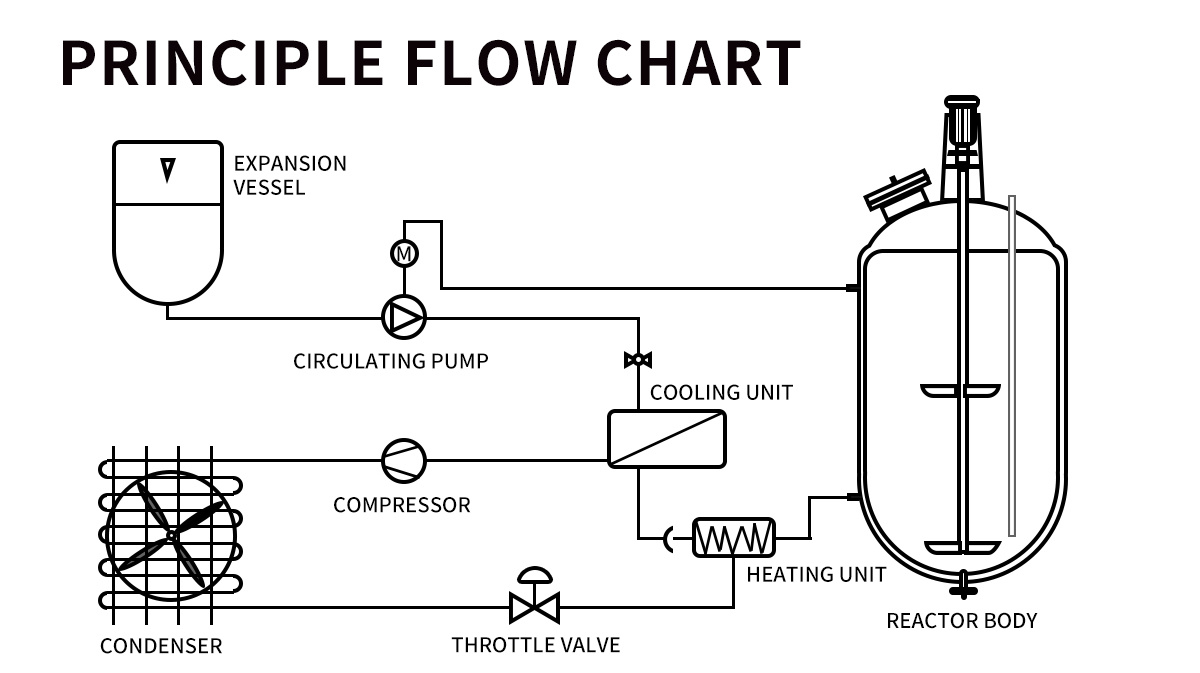

The heating circulator can realize dynamic temperature control from -25 ℃ to 200 ℃. It also has heating and cooling functions. The product has high efficiency, fast speed and simple filling. The whole liquid circulation is a closed system, without oil mist and water absorption, which ensures the safety of the experiment and the service life of the heat conduction medium. Using international brand compressors and circulating pumps, the performance is stable and the quality is reliable; the product has safety functions such as self-diagnosis function, refrigerator overload protection, high-voltage switch, overload relay, thermal protection device, etc.

keyword: constant temperature;Reaction bath

Classification: Temperature Control Unit

- Product Description

-

Model

GDX-302A

GDX-303A

GDX-306A

GDX-309A

GDX-312A

GDX-318A

Technical data

Temperature range

-30~200℃;±0.5℃

Ambient temperature(℃)

≤30℃

Ambient humidity

60%

Voltage(V)

220

380(Optional 3P 220V/3P 480V)

Phase(P)

1

3

Frequency(Hz)

50/60

Power(Kw)

2.8

4.5

7.7

12

15

23

Heating capacity(Kw)

2

3

4.5

6

9

15

Cooling capacity(w)

RT

2200

3400

7500

11500

15750

31428

0℃

1600

2100

5500

8600

11000

20214

-25℃

1000

1800

2100

3200

4300

7000

Temperature sensor

PT100

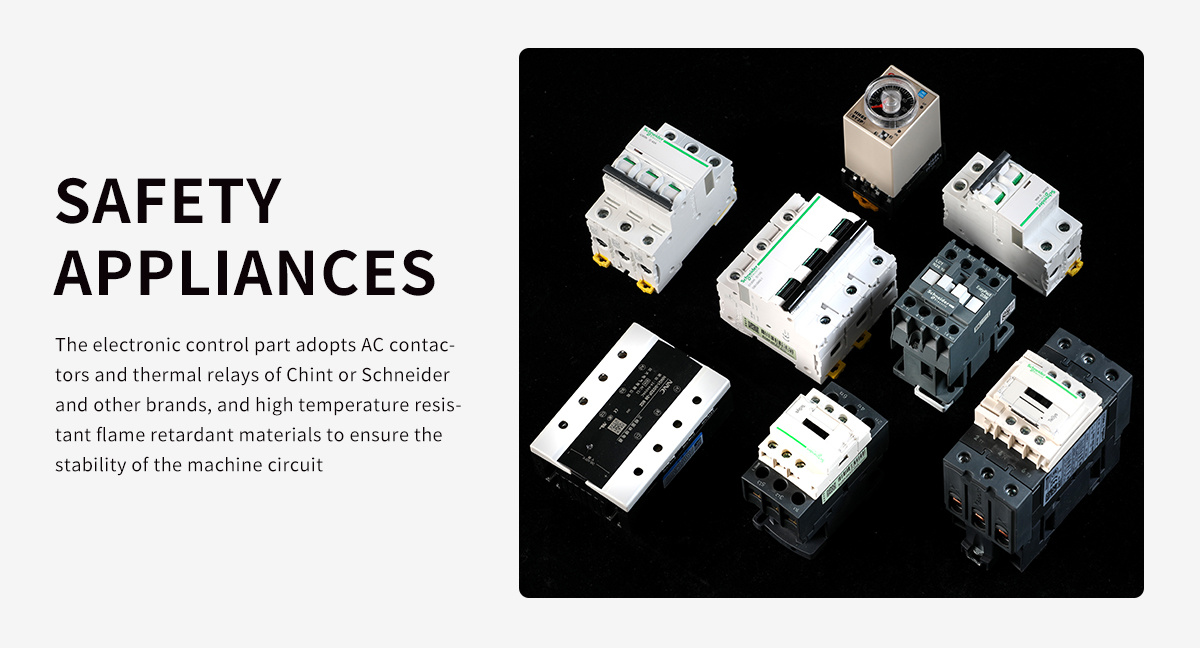

Protection

Overvoltage, time delay, overcurrent, overheating, leakage, protector

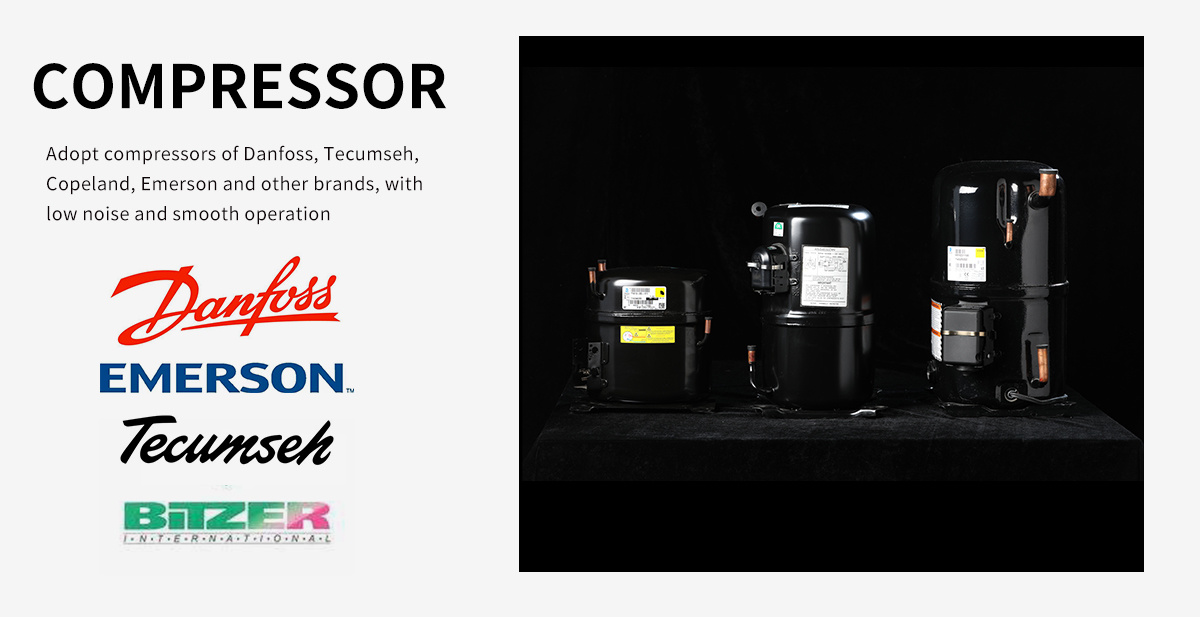

Compressor

Type

Closed

Brand

Panasonic

Tecumseh/Danfoss/Copeland

Power(Kw)

0.73

1.25

2.25

3.75

4.5

6

HP

1

1½

3

5

6

8

Quantity

1

1

1

1

1

1

Refrigerant

R404A

Condenser

Type

Air cooling/water cooling

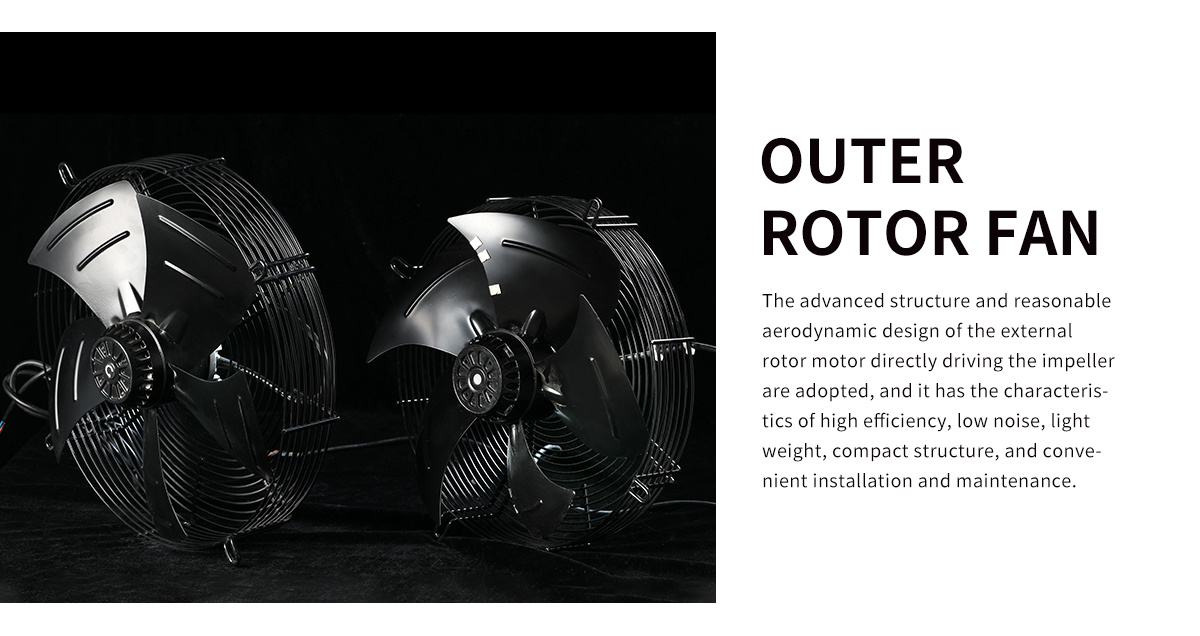

Fan type

External rotor axial flow fan

Quantity

1

2

Evaporator

Type

Plate heat exchanger

Tank volume(L)

7

7

10

17

35

50

External circulation adapter size

G1/2" external interface

G3/4" external interface

G1" external interface

Circulating pump

Type

Shield pump

Vortex pump

Brand

Shanghai Jingyi

Aulank

Power(w)

100

250

370

370

750

Current(A)

1

1

2.1

3.5

3.5

3.5

Rated head(m)

6

6

8

12

12

12

Rated flow(L/min)

25

25

25

35

35

70

Appearance dimension

Weight(Kg)

60

90

130

170

220

340

Packing weight(Kg)

80

115

150

220

290

430

Chiller size

Length(mm)

540

620

710

770

970

1200

Width(mm)

420

540

580

670

800

970

Height(mm)

800

920

1090

1180

1350

1580

Packing size

Length(mm)

610

680

770

840

1040

1280

Width(mm)

510

620

660

760

890

1050

Height(mm)

870

1100

1220

1340

1520

1760

*PLC

Control system

Siemens S7-200 smart PLC

Programming

5 programs can be written, each with up to 40 steps

Control model

Material temperature and equipment outlet temperature can be switched automatically

Protocol

Modbus RTU protocol RS485 interface (optional RS232 Ethernet)

Control panel

7-inch Siemens color touch screen (optional 10 inch)

Data export

Support USB flash disk data export, and export temperature data in TXT format

Packing list

2 sets of adapter valves, one roll of raw meal

2 stainless steel insulated hoses

Operation instructions

All data are measured in the factory, and users will have errors in the process of use

*PLC for optional PLC part data, it is not applicable if there is no PLC

Previous Page

Related Products

Message consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!